5 Simple Techniques For American Plastics

American Plastics Can Be Fun For Everyone

Table of ContentsA Biased View of American PlasticsThe Buzz on American PlasticsAmerican Plastics Fundamentals ExplainedAbout American PlasticsNot known Incorrect Statements About American Plastics

A little research can aid you with time. It is difficult to judge its top quality initially look with the appearance of HDPE pipe fitting, numerous issues are revealed when using, so we can only have a correct judgment after usage. It is necessary to pick HDPE pipe fittings made by a specialist producer with a good credibility and online reputation.

A technological specialist is essential for an excellent item, particularly in the production industry, due to the fact that a tiny blunder will cause the failure of the entire project. HDPE pipelines can change concrete pipelines in field systems to conserve time and expense of repairing broken or ruptured pipes. HDPE pipe is likewise a more economical alternative contrasted to other piping materials in regards to operating and installation prices.

Little Known Facts About American Plastics.

HDPE pipes are made with solid straight or curved sections. The pipelines are not breakable and can be conveniently put right into a rounded location without added jointing or welding.

It has reduced stress and stormy turbulence, especially at high circulation prices. Its 'non-adhesive' particular makes it ideal for retaining the residential or commercial properties of hydraulic liquids. Even HDPE tin tubes are formed in two phases to smooth out the inside. Chemicals resistant to HDPE pipelines can contaminate the pipe. The pipeline does not deal with chemicals and does not shed warm or electricity.

HDPE pipes are normally solid and immune to damage brought on by exterior tons, high pressure or resonance - https://www.storeboard.com/americanplastics. The pipes can endure handling and bend even in winter. Safe eyeliner HDPE internal tubes Smooth Line Pipe Sliding lining utilizing roller combinations Pipeline explosion Plastic plumbing systems Building of brand-new pipelines Corrosion resistance, no dripping, high sturdiness

Warmth assimilation, while its obstacles exist, can create solid and reputable joints. Answers: The toughness and durability of HDPE can be gauged by its capacity to withstand temperature levels of around 248F in the short-term or also a continuous 230F. If your application consists of gas and liquid to accessibility and increase those temperature levels, HPDE piping is a reputable service.

Indicators on American Plastics You Should Know

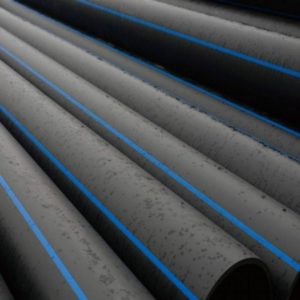

For instance, a drinkable water line/potable water pipeline is constantly dark with blue red stripes and pipelines travelling through liquids, liquids under stress, and process gases are always filled with a yellow or black jacket with yellow lines. HDPE pipeline product have been used in the general industry for over 50 years and their results are amazing, building self-confidence among manufacturers that they are more focused on HDPE pipe solutions.

Times given that 1991 Removal of resin demands with gauge and adjustment. In the tension fracture resistance test the cell division demands were damaged. It is reasonable to end that HDPE pipe developed today may have.

Each size group is made remembering the needs of pressure, circulation price, and ecological factors of the desired application. By matching the right HDPE pipeline dimension to its use, designers and professionals can optimize efficiency and extend the life expectancy of their piping systems. Dimension and size are interrelated concepts in the context of HDPE pipes.

Some Known Details About American Plastics

As specified earlier, pipes with reduced SDR worths are able to endure greater stress, which is an essential factor to consider in the choice process for jobs that involve high stress or essential applications. HDPE Pipe for Oilfield. Selecting a pipeline with an unacceptable SDR might bring about system failing, safety and security dangers, and pricey repair services. Picking the right HDPE pipeline size is critical for the success and effectiveness of any type of piping system

Application Specifics: Tailor your pipeline dimension choice to the certain demands of its application, whether for metropolitan, commercial, or other usages. Recognizing exactly how the HDPE pipeline will be used, the awaited circulation rates and the pressure needs are critical. For example, high-pressure applications might require a pipeline with a better wall surface density to hold up against the internal tensions, while a lower-pressure, high-flow system might prioritize diameter size to minimize friction loss.

How American Plastics can Save You Time, Stress, and Money.

Adhere to these steps: Examine the Application: Identify the pipe's planned usage, consisting of ecological variables and service problems. Determine Flow Prices: Use industry-standard computations or software to estimate the peak and standard circulation rates. Understand Stress Needs: Identify the pressure rating required based upon system demands. Refer to SDR: Examine the conventional measurement ratio to discover a pipeline that can take care Get More Information of the necessary stress.

Choosing the best HDPE pipe dimension is a fragile equilibrium between various technological specs and useful needs - https://trello.com/w/americanplastics/. However, with cautious consideration and precise computations, you can guarantee the size of the pipeline you select will offer your requirements effectively and successfully. Selecting the proper HDPE pipeline size is critical for system performance, durability, and cost-effectiveness

Understanding these elements will make certain ideal performance and compatibility throughout your piping system - hdpe pipe fittings Midland TX. The anticipated circulation price or volume of the liquid being transferred is one of the primary components in pipe size selection. A pipeline that is too tiny can restrict circulation, causing stress loss and prospective clogs, while an extremely large pipeline may cause unnecessary expense and minimized system efficiency